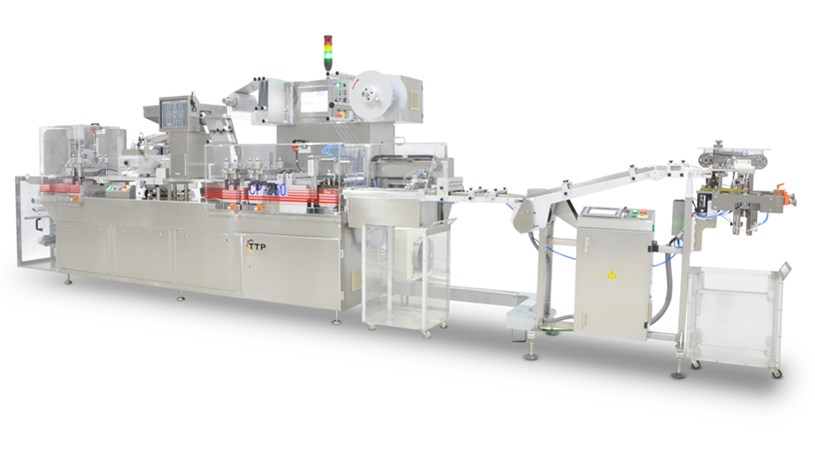

Automatic Blister Packing Machine – CE Certified, Modular & Flexible Design

- Tiến Tuấn’s automatic blister packing machine is manufactured according to CE standards and complies with GMP production requirements. It is suitable for pharmaceutical, nutraceutical, and healthcare manufacturing that demands high stability, productivity, and precision in packaging operations.

- The machine features an intelligent modular design that allows easy upgrades or expansion without altering the main structure, adapting quickly to changes in production needs.

Key Advantages

- Stable operation under all conditions, including speed changes and restarts after stoppage.

- In-process adjustments possible without pausing the machine → saving time and improving operational efficiency.

- Quick-change tooling with compact, minimal-format parts enables fast mold replacement and ensures high precision.

- Low noise level, creating a worker-friendly environment.

Optimized Operating Principle – Step-by-Step Accuracy

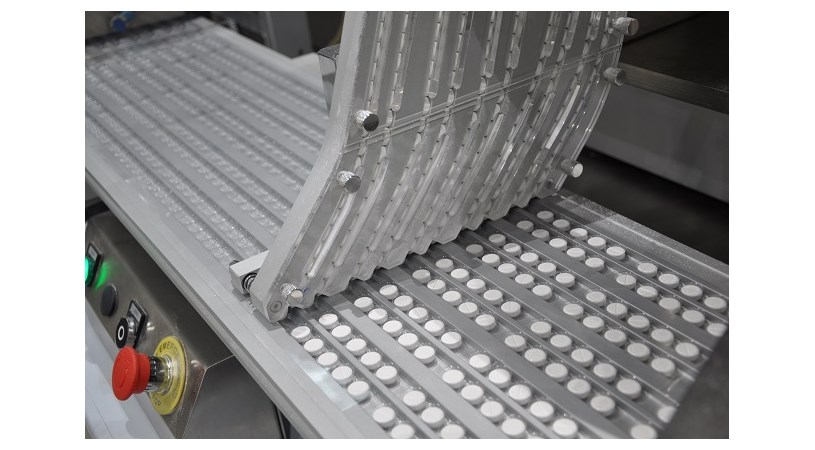

Tiến Tuấn automatic blister packing machine operates on an intermittent sequential mechanism, ensuring high accuracy and control throughout the entire packaging process. Key stages include: forming, tablet/capsule feeding, sealing, batch coding, and final blister cutting.

- PVC/PVDC is formed using heating, while aluminum (Alu) is shaped through cold deformation.

- Heat sealing ensures blister integrity, supported by a descending conveyor system that protects the film and enhances durability.

- Smart sensors align print marks accurately, ensuring perfect positioning for logos or product information on the packaging.

- Integrated cutting and batch coding stations save space and deliver a clean, professional blister appearance.

Specifications

| Unit | CP-160 | CP-205 | CP-250 | B-300 | B-600 | |

| Capacity | blister/minute | max.200 | max.250 | max.300 | max.300 | max.600 |

| Width of forming foil/ sealing film | mm | max.160 | max.205 | max.250 | max.250 | max.250 |

| Draw-off length | mm | max.110 | max.120 | max.140 | max.140 | max.240 |

| Effective surface | mm | 150x108 | 215x118 | 240x138 | 240x138 | 240x238 |

| Forming depth | ||||||

| Standard (PVC/Alu) | mm | max.12 | max.12 | max.12 | max.12 | max.12 |

| Special | mm | max. 18 or 32 | max. 18 or 32 | max. 18 or 32 | max. 18 or 32 | max. 18 or 32 |

| Working speed | ||||||

| For PVC/Alu blister | stroke/minute | max.60 | max.60 | max.60 | max.60 | max.60 |

| For Alu/Alu blister | stroke/minute | max.50 | max.50 | max.50 | max.50 | max.50 |

Blister packaging machine B-600 for productivity up to 600 blisters / minute. The machine is suitable for products that need high productivity.

Blister Packing machine B-600 has option to fully covered with canopy from foil supply, forming area, feeding area until sealing, finished cut product, suitable for containment purpose and comply FDA requirements.

Servo- driven technology for accurate indexing via digital setting.

Detect the Alu cold foil down to 25 μm, using infrared ray. Blister with hole will not be fed (by matrix feeder) and to be auto rejected.

The fill control is inspected by different options of color camera.

Camera will detect the mis-filled blister, broken table, wrong shape product, wrong color tablet, chipped tablet, empty blister ,... Robot arm to "pick & place" good blister by Servo drive to place on discharge conveyor. Defective blister will be strapped down into reject container.

There're different types of auto feeder to be suitable for many different shapes of products.

Blister packaging machine B-300 productivity is max. 300 blisters /minute.

Blister Packing machine B-300 is fully covered with canopy from foil supply, forming area, feeding area until sealing, finished cut product, suitable for containment purpose and comply FDA requirements.

Less noise, only 72 dB.

Adjustment is allowed during operation.

Quick changeover thanks to quick clamp, compact format and few number of change parts.

Servo- driven technology for accurate indexing via digital setting.

Detect the Alu cold foil down to 25 μm, using infrared ray. Blister with hole will not be fed (by matrix feeder) and to be auto rejected.

Online printing helps to print barcode, expiry date, manufacturing date on line,… on lid foil of blister.

Besides, the Blister can be equipped with Optical Variable data Verification system with Character Recognition (OCV/OCR).

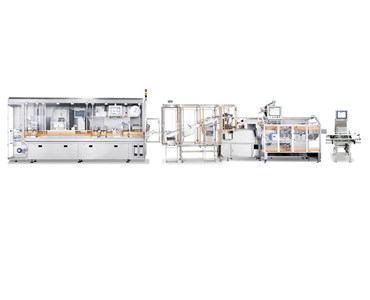

It can be connected to the Automatic Cartoning machine to make a fully automatic Blister-Cartoning line.

Blister packaging machine CP-250 for productivity up to 300 blisters / minute. The machine is suitable for packing blister PVC/Alu, PVDC/Alu, Alu/Alu, for tablet, capsule, vial, ampoule, syringe,...

Compact mold, quick changeover without tools.

Servo- driven technology for accurate indexing via digital setting.

The fill control is inspected by different options of color camera. Robot arm will pick qualified blister and placed on discharge conveyor, defective blister will be strapped down into reject container.

Pin hole detecter can detect the Alu cold foil down to 25 µm, using infared ray.

It is suitable for many different methods of automatic feeding depending on specific product such as Brush box feeder, Matrix feeder, Vibration disk & Feeding rail, Roller feeder, Auto feeder for vial/ampoule/syringe,...

It can be connected to the Automatic Cartoning machine to make a fully automatic Blister-Cartoning line.

Blister packaging machine CP-160 gives productivity max. 200 blisters / minute.

Compact mold, quick changeover without tools.

Blister machine model CP-160 is suitable for small scale production plants that do not require a high level of automation.