The High speed Mixer & Granulator is a very important equipment the granulation line, which directly affects the product quality and greatly affects the next production processes.

The High speed Mixer & Granulator is a very important equipment the granulation line, which directly affects the product quality and greatly affects the next production processes.

For R&D and pilot production scale, we have 2 types of designs:

- The design of a fixed vessel Mixer

- Interchangeable design, allowing to change different vessel sizes on the same body

In addition, we design and manufacture 2 types of High speed Mixer & Granulator, which are:

- Bottom Drive High speed Mixer & Granulator, with the drive at an underneath, called HMG-xxx

- Top Drive High speed Mixer & Granulator, with the driver is at upper, called TMG-xxx

Tien Tuan has fixed vessel mixer and interchangeable Mixer.

The mixer fixes a pot size of 5kg, 10kg, 5kg, or 20kg.

High Speed Mixer & Granulator HMG-5/10/20 is a flexible machine for laboratory and for pilot production. The machine is easy to operate and conforms to cGMP.

Mixing/granulating bowls of 15, 30 and 60 liter can be installed.

When changing the bowl, the chopper, chopper motor and discharge cylinder are also exchanged.

Scale-up to production scale is available.

In addition, we can design interchangeable different vessel sizes upon request.

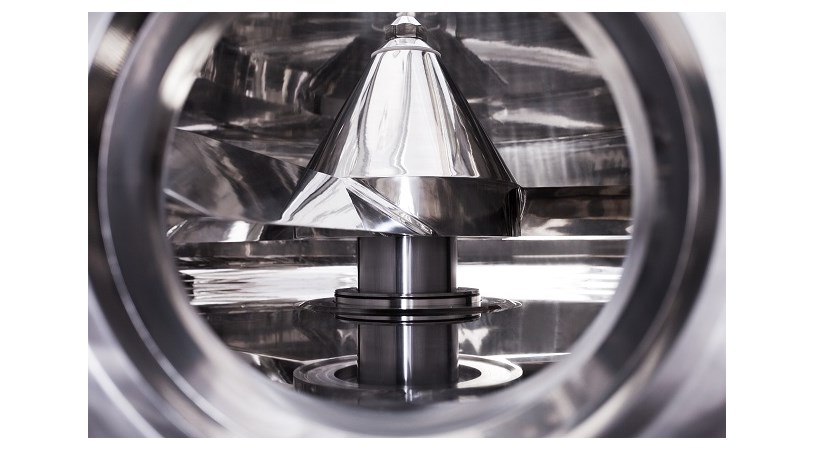

The High speed Mixer & Granulator is designed with the drive placed at underneath.

Tien Tuan's High speed Mixer & Granulator is available for free-standing or through-the-wall installation.

The ideal position for "through-the- wall installation" is the corner of the production room against the wall to share with technical area behind. This requires minimum space occupation, fewer external surfaces to clean, allows operating panel/ PC and chopper drive to be installed through the wall.

The main drive, pneumatic pipe, valves,… are placed under machine platform, with stainless steel clad to cover. The lower part of the machine is left uncovered for easy cleaning and installation.

Vacuum pump, WIP valves, granulating liquid pumps (complete with the controls hoses,…) are all integrated in a GMP correct way. Easy cleaning of the outside surfaces.

Top drive Mixer & Granulator TMG-200D is the advanced achievement in granulating technology with design of mixer bearing and drives for the agitator and chopper positioned above the process vessel, and separated

from clean room. It overcomes any obstacles of cleaning in traditional design of bottom drive mixer & granulator.

High speed mixer & granulator with top drive design so that mixing vessel can be lifted up and down vertically. By doing this, cleaning validation is more convenient because operator can easily check or take sample after cleaning. Furthermore, at discharge of the mixer, there is an inline wet milling station which can minimize manual steps after mixing. As a result, GMP area is saved for other purposes.

HIGHLIGHTS

Total containment.

Most effective for small scale, organic solvents, temperature sensitive product or low quantity of binder liquids.

Suitable for herbal drug, or material mixed at high load.

Uniform mixing, stable, porous granules.

Fully empty without remain.

Efficient WIP/CIP.

Safety: 16 bar pressure resistance.

Flexible: to be stand-alone as Single pot or in combination with fluid bed dryer to maximize efficiency.