Cleaning

Cleaning processing equipment is a must in the pharmaceutical manufacturing process, and this is a challenge. All cleaning methods, type of production equipment, surfaces to be cleaned, detergent selection and temperature should be considered when establishing the cleaning procedure. Cleaning confirmation method is required. All cleaning procedures must be standardized and documented in accordance with FDA's cGMP regulations.

Why Clean Pharmaceutical Processing Equipment?

- Maintain product quality.

- Remove all trace ingredients to prevent the transfer of ingredients from one product to the next. This is especially important when multiple products are produced on the same equipment.

- Prevent equipment malfunctions that may lead to product contamination.

- Provide a clean surface for disinfection. Surfaces cannot be properly sanitized or disinfected if they are not thoroughly cleaned first.

-Comply with local and international standards and regulations to ensure consumer safety and avoid legal issues.

- Increase plant performance and productivity by diminishing waste, maintaining equipment and preserving product quality.

- Enhance worker safety by providing a clean working environment and smoothly functioning equipment.

Tien Tuan provides cleaning solutions for production equipment. Once equipment is cleaned, helping to maintain product quality, increase plant efficiency and productivity, create a clean production environment, avoid risk of cross-contamination and ensure compliance with domestic regulations and It ensures user safety and avoids legal problems.

- Automatic cleaning function integrated on each machine

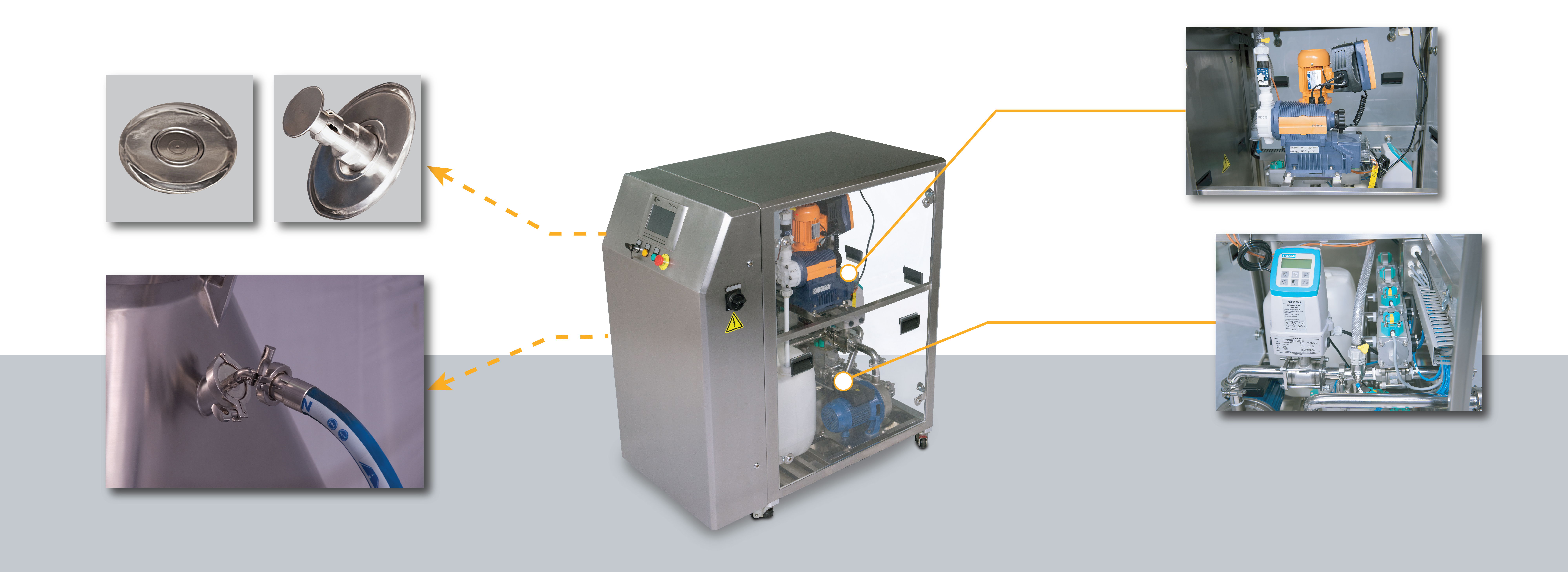

- Mobile high pressure washing machine

- Semi-automatic washing station